In the world of modern electronics, two crucial components often work together to provide efficiency, precision, and functionality in various devices: PCBA (Printed Circuit Board Assembly) and IR sensors (Infrared Sensors). These elements are integral in everything from consumer electronics to industrial systems, offering a wide range of applications across different industries. In this article, we’ll break down the meaning of PCBA and explore the role of IR sensors, focusing on how they interact in today’s technological landscape.

What is PCBA?

PCBA stands for Printed Circuit Board Assembly, a critical step in the manufacturing of electronic devices. It involves attaching electronic components to a printed circuit board (PCB) to create a functional unit. The PCB itself serves as the foundation, providing physical support and electrical connections for various components such as resistors, capacitors, integrated circuits, and connectors.

PCBA is essential in producing devices like smartphones, computers, medical devices, and automotive systems. The process typically involves several stages:

- Soldering: Components are soldered onto the PCB either through wave soldering, reflow soldering, or hand soldering.

- Placement: Using automated machinery, components are placed accurately on the board.

- Inspection and Testing: After assembly, PCBs undergo various testing methods like flying probe tests, X-ray inspections, and functional testing to ensure they meet the required standards of performance and quality.

In the context of mass production, PCBA ensures a streamlined, repeatable process that produces reliable electronic products at scale.

What are IR Sensors?

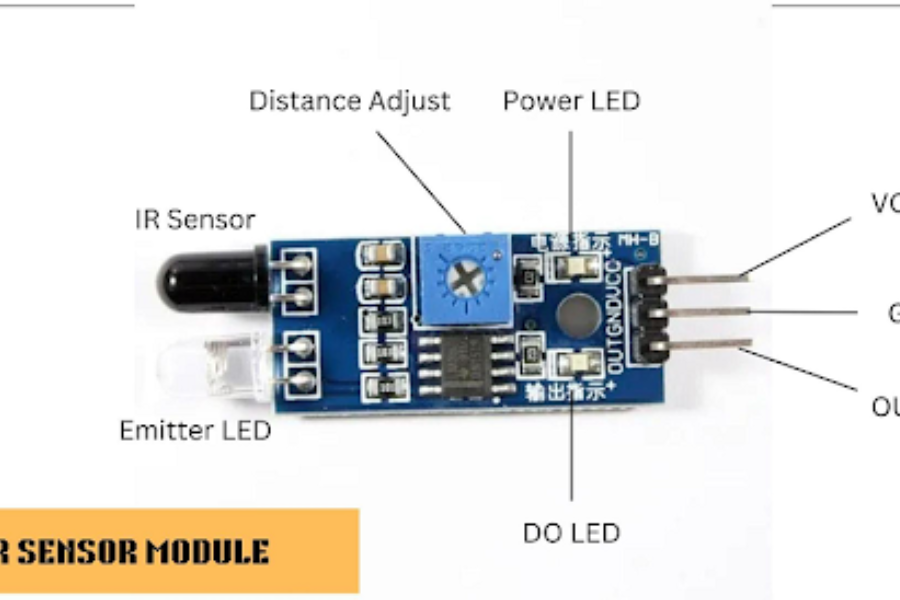

IR Sensors (Infrared Sensors) are devices that detect infrared radiation emitted by objects in their environment. These sensors work based on the principle that all objects emit infrared light depending on their temperature. The most common application of IR sensors is for motion detection, temperature sensing, and night vision systems.

IR sensors can be classified into two major types:

- Active IR Sensors: These sensors use an infrared light emitter (usually an LED) and a receiver. The emitter sends out infrared light, and when this light is reflected by an object, the receiver detects the reflection, helping in detecting the presence or movement of the object.

- Passive IR Sensors (PIR Sensors): These sensors detect the infrared radiation naturally emitted by warm objects, such as humans or animals. PIR sensors are widely used for motion detection in security systems, automated lighting systems, and human-computer interaction.

IR sensors are commonly used in applications where light is insufficient, or the object needs to be detected at a distance. They are key components in various consumer products like:

- Smartphones and Tablets: For features like face detection and proximity sensors.

- Home Automation: For controlling lighting and heating based on the presence of people.

- Healthcare Devices: To monitor body temperature without direct contact.

The Intersection of PCBA and IR Sensors

PCBA plays an integral role in the function of IR sensors. The PCB assembly provides the necessary structure for the sensor’s components and ensures proper electrical connections. In IR sensor systems, the PCB is where key components, such as the IR emitter, receiver, processing chips, and sometimes power supplies, are mounted. The quality of the PCBA directly impacts the performance and reliability of IR sensors, making precision and quality control during assembly crucial.

For example, in a motion detection system, a PIR sensor’s PCB assembly includes not only the sensor itself but also the circuitry required for signal processing, power management, and communication with the rest of the system. PCBA manufacturers must ensure that all components are securely soldered, and the board is free of any defects that could interfere with the IR sensor’s ability to accurately detect motion or changes in temperature.

Why PCBA is Crucial for IR Sensor Applications

- Precision and Reliability: For IR sensors to function properly, they must be finely tuned and free of defects. A high-quality PCBA ensures that the sensor’s circuits and components are connected securely and without any faults.

- Customization: IR sensors are used in a wide range of applications, from industrial machinery to consumer electronics. PCBA allows for flexible design and the ability to customize sensors for specific needs, ensuring the product performs optimally.

- Integration: Modern IR sensors are often embedded into larger systems, such as smartphones or home automation devices. A well-manufactured PCBA ensures that the IR sensor integrates seamlessly with other components of the system, providing the desired functionality.

Conclusion

In summary, PCBA and IR sensors are two crucial components in the development of modern electronic devices. PCBA provides the foundation for the electrical and mechanical components, while IR sensors offer a wide range of functionalities, from motion detection to temperature sensing. Together, these technologies contribute to the innovation and performance of devices that are shaping our daily lives.

Whether in smart homes, automotive systems, healthcare devices, or consumer electronics, the combination of high-quality PCBA and advanced IR sensor technology ensures the reliable operation of cutting-edge products that improve convenience, security, and efficiency.

Stay updated with the latest news and notifications LET MAGAZINE Best Regards!